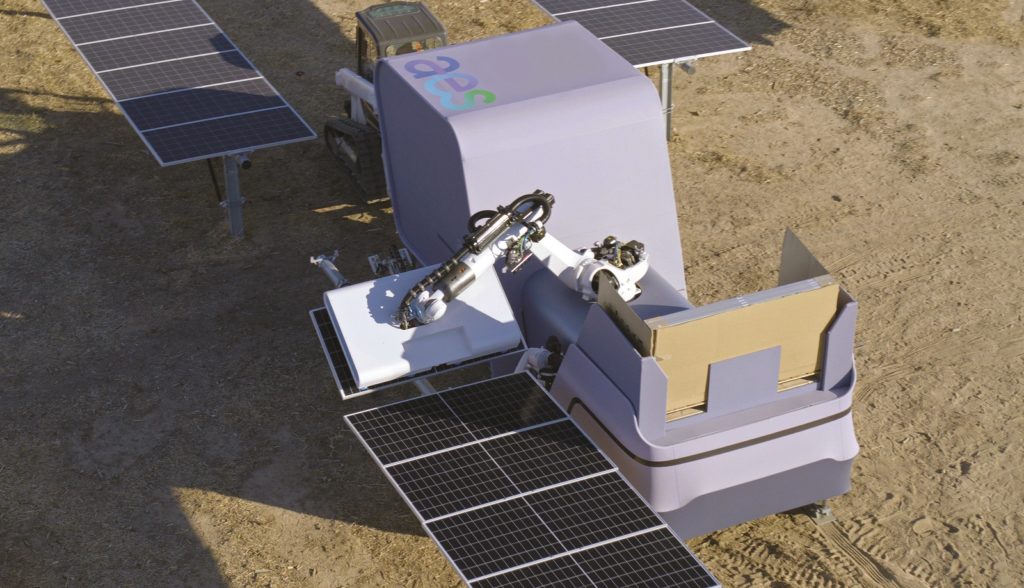

Researchers developed a robot that can conduct experiments more efficiently and sustainably in order to generate a variety of new semiconductor materials with acceptable properties.

The researchers have already shown that the new RoboMapper system can quickly find new perovskite materials with increased stability and solar cell efficiency.

“RoboMapper allows us to conduct materials testing more quickly, while also reducing both cost and energy overhead—making the entire process more sustainable,” says Aram Amassian, corresponding author of the paper and professor of materials science and engineering at North Carolina State University. The research, “Sustainable Materials Acceleration Platform Reveals Stable and Efficient Wide Bandgap Metal Halide Perovskite Alloys,” appeared in the journal Matter on July 25.

In traditional materials research, a researcher must prepare a sample before testing it with various instruments in a series of processes. This entails positioning, aligning, and calibrating samples as needed to acquire data. Consider it an assembly line that is both time-consuming and energy-intensive to power the necessary instruments.

Earlier attempts to automate this process depended heavily on automating the assembly line, with one sample per chip traveling through the full data collection process. This improves speed, but each step must still be completed with one sample at a time.

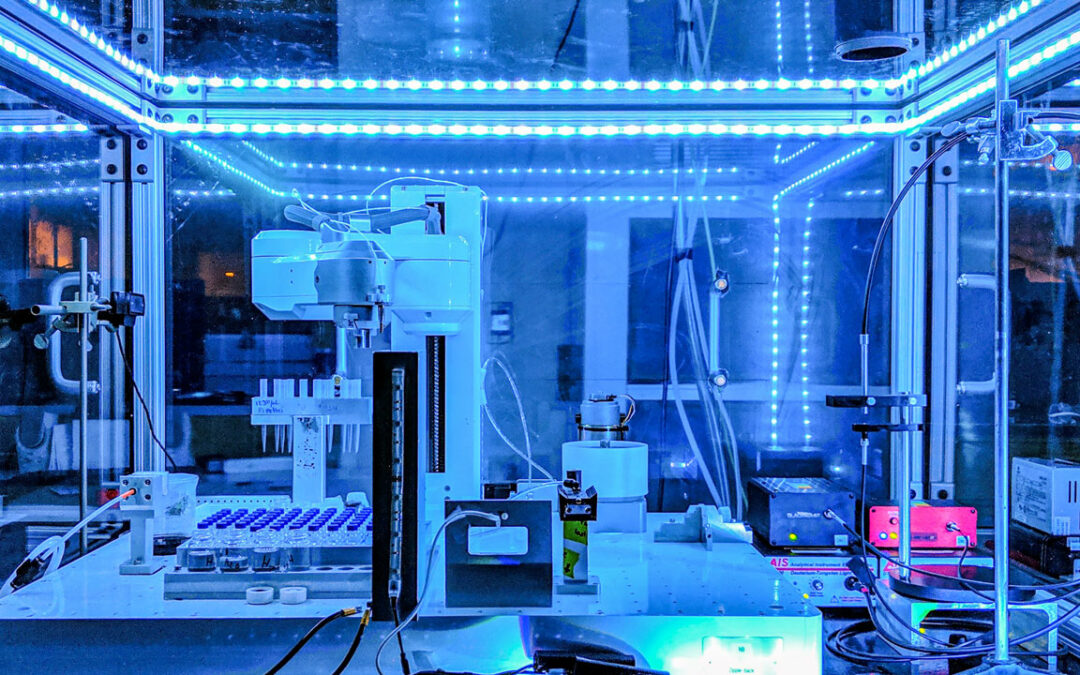

“RoboMapper also automates this process, but it places dozens of samples on each chip by miniaturizing the material samples with the help of modern printing,” Amassian explains. “It still performs each step of the data collection process, but it does so for multiple materials in parallel, saving time and energy.”

“This makes searching for new materials far more efficient, cost effective, and sustainable in terms of our carbon footprint,” says Tonghui Wang, the paper’s primary author and a Ph.D. student at NC State. “It’s nearly 10 times faster than previous automated techniques.”

To validate this, the scientists contrasted the environmental impact of traditional materials research and data collection to the RoboMapper.

“It was remarkable to find that characterization is the major source of greenhouse gas emissions in materials research,” says environmental economist Luca Serrano-Luján, co-author of the article and researcher at Rey Juan Carlos University and the Technical University of Cartagena. “The RoboMapper’s ability to streamline the data collection process by placing dozens of materials on the same chip reduced greenhouse gas emissions by tenfold.”

To illustrate RoboMapper’s utility, the researchers first concentrated on perovskite materials. Perovskites, which are distinguished by their crystalline structure, absorb light better than silicon. This means that perovskite solar cells can be thinner and lighter than silicon solar cells while still converting light into power, making them a focus for research into next-generation solar systems.

The researchers concentrated on perovskite stability, which is one of the most difficult difficulties in the area.

“Basically, the problem is that when exposed to light, perovskite materials degrade, losing the properties that made them desirable in the first place,” Amassian explains. “We’re looking for ways to engineer these materials so that they’re stable—that is, that they keep their desirable properties even when exposed to light.”

During the technology’s proof-of-concept demonstration, the researchers made their first big discovery with RoboMapper.

The researchers gave RoboMapper the duty of creating alloys from a predefined set of elements. RoboMapper then created samples with 150 different alloy compositions and tested them using optical spectroscopy, X-ray structural analyses, and stability testing.

The RoboMapper tests were designed to determine whether an alloy was suitable for tandem solar cells, which meant it had the crystalline structure of a perovskite, a desirable set of optical properties known as the band gap, and was stable when exposed to intense light. This experimental data was then utilized to build a computational model that predicted which alloy composition would have the best combination of desired qualities.

The researchers next tested both RoboMapper and traditional laboratory approaches to create the appropriate alloy.

“Using the specific suite of elements we confined ourselves to for this proof-of-concept work,” Amassian says, “we are able to quickly identify the most stable composition from a possible set of perovskite alloys at a target band gap.” “The material we discovered using RoboMapper was also more efficient at converting light into electricity in solar cell devices.” Our traditional methodologies validated the RoboMapper results.

“One of the reasons RoboMapper’s experiments produced such useful data is that the specific suite of experiments we used is based on previous work that informs our understanding of the relationship between what we can see in optical tests and the stability of perovskite materials.”

“Next steps in this work include expanding the range of potential alloys for testing in RoboMapper,” Amassian says. “We’re willing to collaborate with industry partners to find new materials for photovoltaics or other applications.” And, with the help of the Office of Naval Research, we’re already utilizing RoboMapper to learn more about materials for organic solar cells and printed electronics.”

Ten of the paper’s authors are members of NC State’s ORganic and Carbon Electronics Laboratories (ORaCEL), an interdisciplinary team of researchers dedicated to accelerate the development of new semiconductor materials for a variety of applications.

Download The Radiant App To Start Watching!

Web: Watch Now

LGTV™: Download

ROKU™: Download

XBox™: Download

Samsung TV™: Download

Amazon Fire TV™: Download

Android TV™: Download